Experience the power of automation with Ritech, your partner in innovative manufacturing solutions.

Welcome to Ritech, your trusted partner in advanced automation solutions. We specialize in integrating state-of-the-art technology into your production lines, ensuring enhanced efficiency, superior product quality, and significant cost savings. Discover how Ritech’s expertise can transform your manufacturing processes.

Our Expertise

At Ritech, we bring extensive experience across various industries, including metal die-casting, plastic injection molding, aluminum profile processing, and metal stamping. Our team of professionals is dedicated to delivering customized automation solutions tailored to meet your specific needs.

Why Choose Ritech?

1. Comprehensive Needs Analysis

- Detailed Assessment: We thoroughly analyze your current production line, identifying areas for improvement and automation potential.

- Objective Setting: We work with you to establish clear goals, such as increasing production efficiency, reducing labor costs, and improving product quality.

2. Advanced Process Design and Optimization

- Streamlined Processes: Our experts optimize your existing production processes to eliminate unnecessary steps and enhance workflow efficiency.

- Custom Workstation Design: We design and layout each workstation to ensure seamless operations and maximum productivity.

3. Cutting-Edge Technology Selection

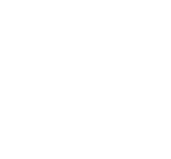

- Robotic Automation: We deploy the latest in robotic technology, including high-precision robotic arms, automated conveyor systems, and assembly equipment.

- Sophisticated Control Systems: Our solutions include PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems for reliable device connectivity and control.

4. Seamless System Integration

- Equipment Connectivity: We ensure all automation equipment is interconnected through robust networks and control systems for efficient data communication.

- Real-Time Data Integration: Utilizing sensors and IoT (Internet of Things) devices, we integrate real-time data into MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) systems for comprehensive monitoring and analysis.

5. Efficient Layout Design and Implementation

- Optimized Layouts: We design your production line layout to facilitate efficient material and product flow, minimizing handling and waiting times.

- Simulation Testing: Our use of 3D simulation software allows us to model and optimize the layout, ensuring feasibility and efficiency before implementation.

6. Phased Implementation and Debugging

- Gradual Integration: We implement automation in phases, starting with specific workstations or stages and gradually expanding to the entire production line to ensure smooth transitions.

- Thorough Debugging: Our detailed debugging process ensures all equipment and systems operate flawlessly, addressing any potential issues promptly.

7. Comprehensive Training and Maintenance

- Employee Training: We provide extensive training for your operators and maintenance personnel to ensure they can efficiently operate and maintain the automated systems.

- Maintenance Plans: Our regular maintenance plans ensure the long-term stability and reliability of your equipment, with quick response times for any repair needs.

8. Continuous Optimization and Improvement

- Data-Driven Enhancements: We continuously optimize your production processes and equipment performance based on real-time data analysis, improving efficiency and quality.

- Feedback Mechanisms: We establish robust feedback mechanisms to gather input from operators and technicians, driving ongoing system improvements.

Case Study: Ritech’s Automation Integration

Discover how Ritech successfully integrated automation into diverse production environments:

1. Metal Die-Casting

- Robotic Arms: High-precision robotic arms ensure consistent quality and efficiency in metal die-casting operations.

- Automated Quality Checks: Integrated quality control systems automatically inspect each cast, reducing defects and waste.

2. Plastic Injection Molding

- Automated Injection Machines: Advanced injection molding machines enhance precision and reduce cycle times.

- IoT Integration: Real-time monitoring and data collection improve process control and maintenance scheduling.

3. Aluminum Profile Processing

- Conveyor Systems: Automated conveyor systems streamline material handling and improve workflow efficiency.

- Custom Workstations: Tailored workstations enhance the flexibility and scalability of production lines.

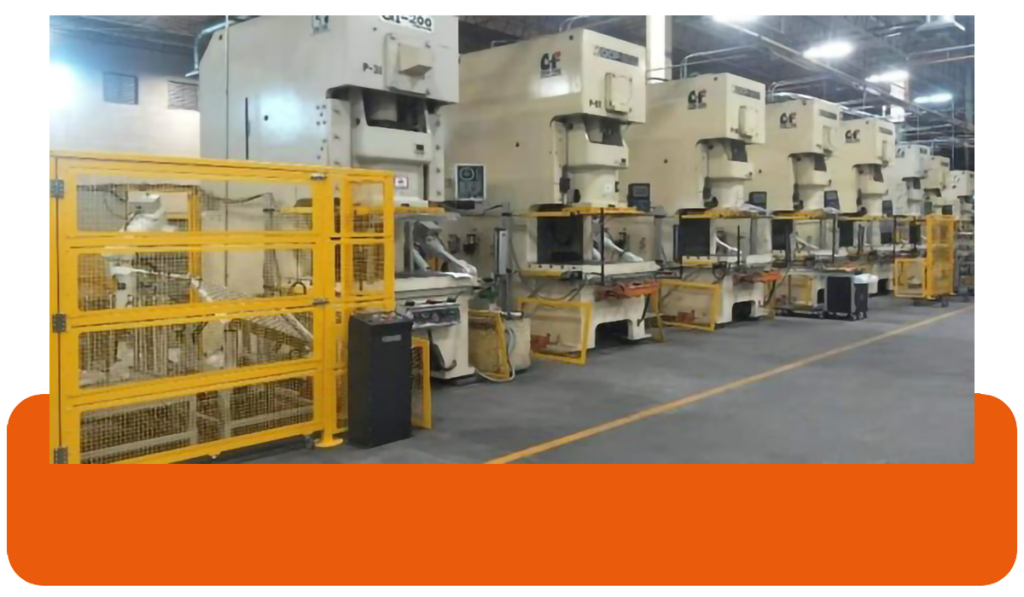

4. Metal Stamping

- Advanced Stamping Equipment: State-of-the-art stamping machines increase production speed and accuracy.

- Integrated Safety Systems: Automated safety features protect workers and ensure compliance with industry standards.

Get Started with Ritech

Transform your production line with Ritech’s automation solutions. Contact us today to schedule a consultation and learn how we can help you achieve unparalleled efficiency, quality, and cost savings. Let’s build the future of manufacturing together!

Why Choose Ritech?

- Customization: Ritech offers customizable production line automation solutions, allowing businesses to tailor automation systems to their specific production requirements, processes, and industry standards.

- Efficiency: Ritech’s production line automation enhances operational efficiency by automating repetitive tasks, reducing manual labor, and optimizing workflows. This results in increased productivity, shorter lead times, and lower production costs.

- Accuracy and Consistency: Automated production lines by Ritech ensure high levels of accuracy and consistency in manufacturing processes, leading to improved product quality and reduced defects.

- Scalability: Ritech’s automation solutions are scalable, allowing businesses to easily expand or modify their production lines to accommodate changes in demand, product variations, or business growth.

- Integration: Ritech’s production line automation seamlessly integrates with existing manufacturing systems, such as ERP, MES, and quality control systems, providing a unified and streamlined production environment.

- Data-driven Insights: Ritech’s automation solutions capture real-time data from production processes, enabling businesses to gain valuable insights into performance, efficiency, and quality metrics. This data-driven approach facilitates continuous improvement and informed decision-making.

- Safety: Ritech prioritizes safety in its automation solutions, implementing safety features and protocols to protect workers and prevent accidents in the production environment.

- Reliability: Ritech’s automation systems are built to be robust and reliable, minimizing downtime and ensuring continuous operation even in demanding manufacturing environments.

- Support and Service: Ritech provides comprehensive support and service for its automation solutions, including installation, training, maintenance, and troubleshooting, to ensure smooth operation and maximum uptime.

Overall, choosing Ritech’s production line automatic offers businesses a strategic advantage by enhancing efficiency, quality, scalability, and competitiveness in today’s dynamic manufacturing landscape.

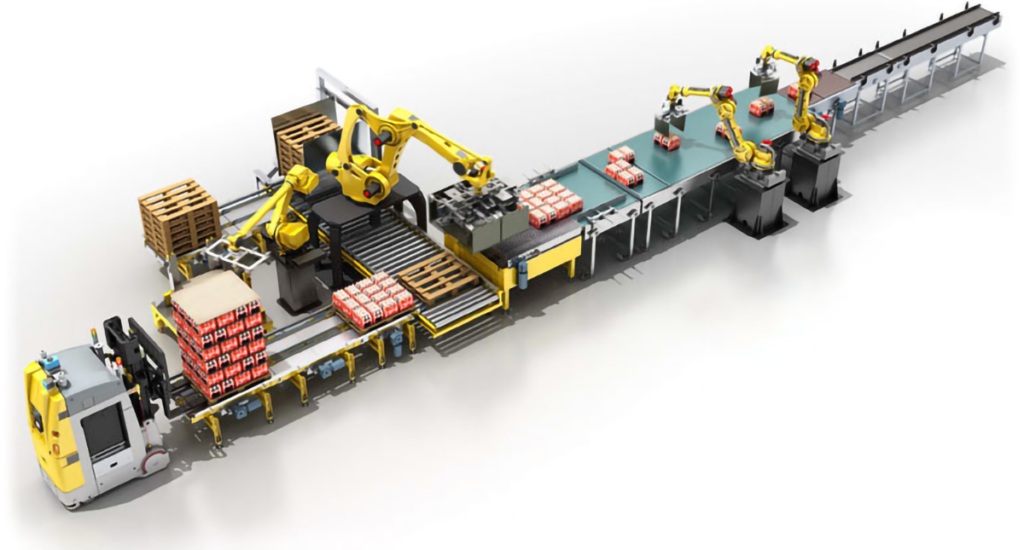

Automatic Box Assembly line

Carton Packing Automatic line

Metal Stamping Automatic line

Tube Bending Automatic line

Aluminum Profile Processing Automation