Cable clamping automation represents a revolutionary solution aimed at significantly improving safety and efficiency in the cable installation process, particularly in situations where conventional methods pose significant risks to operators. Here’s how it works:

1. Enhanced Safety: Traditionally, cable installation on towers requires operators to work at great heights, exposing them to various hazards and safety risks. Cable clamping automation eliminates the need for operators to perform these tasks manually, mitigating the risk of accidents, injuries, and fatalities associated with working at height.

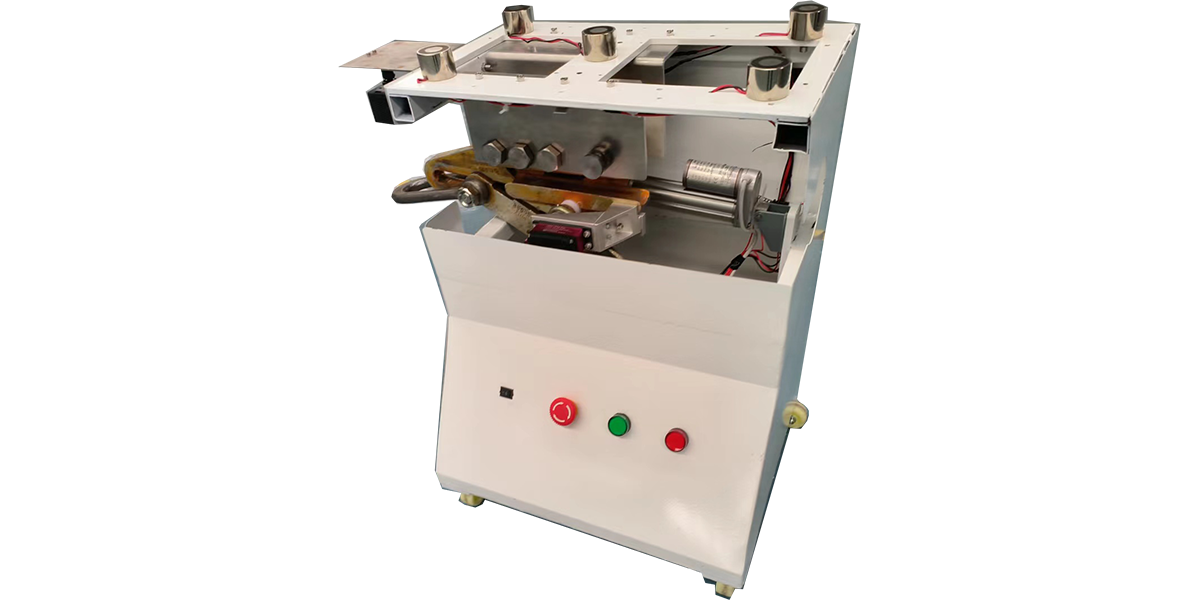

2. Drone-Assisted Operation: The cable clamping machine is equipped with innovative features that enable it to be operated remotely, using drones. Operators can use drones to transport the cable clamping devices to the desired locations on the tower, eliminating the need for manual handling and reducing the risk of falls and injuries.

3. Precise Cable Placement: Once the cable clamping device is positioned using the drone, it can accurately clamp onto the cable that needs to be secured. This ensures precise and consistent cable placement, reducing the likelihood of errors and ensuring optimal performance of the cable installation system.

4. Increased Efficiency: By automating the cable clamping process, productivity and efficiency are significantly enhanced. The automation eliminates the time-consuming manual labor involved in traditional cable installation methods, allowing for faster deployment of cables and reducing overall project timelines.

5. Versatility and Adaptability: Cable clamping automation can be adapted to various types of towers and cable installations, making it suitable for a wide range of applications across different industries. Whether it’s telecommunications, power transmission, or infrastructure projects, this innovative solution offers versatility and adaptability to meet diverse needs.

6. Cost Savings: Beyond safety and efficiency benefits, cable clamping automation can also lead to cost savings by reducing labor costs, minimizing downtime associated with manual processes, and enhancing overall project productivity. Additionally, the reduction in accidents and injuries can result in lower insurance premiums and liability costs.

In conclusion, cable clamping automation represents a groundbreaking advancement in cable installation technology, offering enhanced safety, efficiency, and versatility compared to traditional methods. By leveraging drone-assisted operation and precision clamping technology, this innovative solution is poised to revolutionize the way cable installations are conducted, ensuring safer working conditions and improved project outcomes.