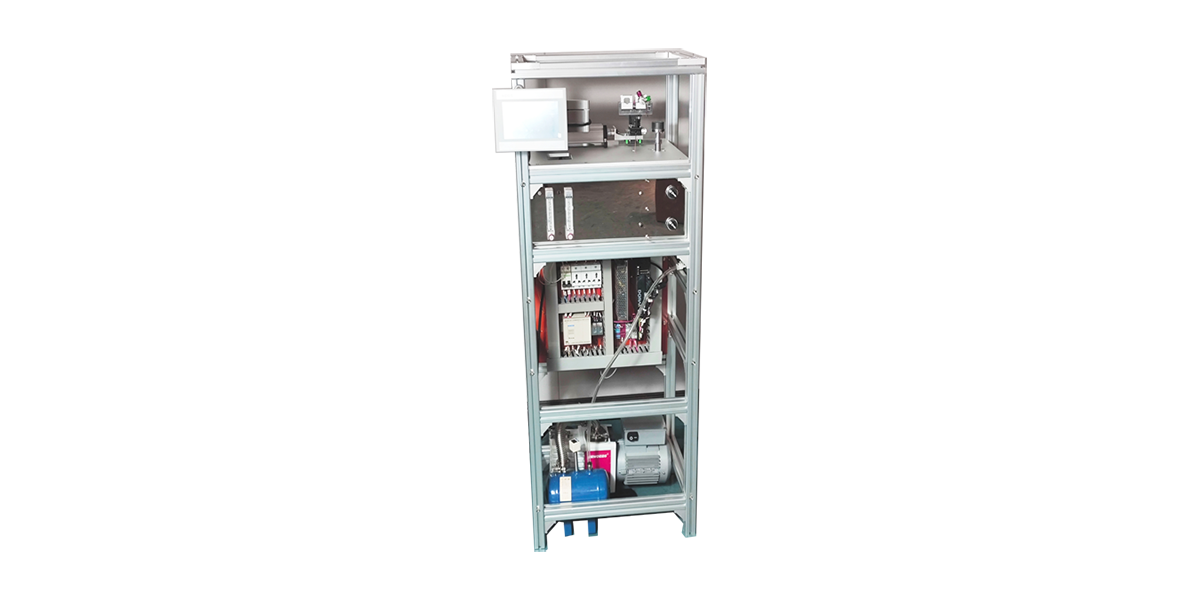

Ritech pioneers cutting-edge automation solutions designed to optimize every aspect of the quartz molding process. Our integrated system combines precise quartz heating, controlled temperature maintenance, vacuum molding, and automatic feeding and unloading functionalities, all seamlessly managed by a sophisticated robotic arm. Additionally, our automation systems feature advanced measurement capabilities, utilizing rulers to ensure unparalleled precision throughout the molding process.

Key Features and Benefits:

- Quartz Heating and Temperature Control: Ritech’s automation solutions incorporate state-of-the-art quartz heating mechanisms, ensuring the material reaches and maintains the precise temperature required for optimal molding conditions. Advanced temperature control systems guarantee uniform heat distribution, essential for consistent and high-quality molding results.

- Vacuum Molding Expertise: Our systems seamlessly transition from the heating phase to the vacuum molding stage, facilitating precise shaping and molding of the quartz material. Through meticulous control of vacuum chambers, we create an ideal molding environment, allowing for intricate designs and exact specifications.

- Automated Feeding and Unloading: Ritech’s automation solutions feature fully automated feeding and unloading mechanisms, facilitated by a robust robotic arm. This arm efficiently handles the feeding of quartz material into the molding chamber and the unloading of finished products upon completion, reducing reliance on manual labor and maximizing operational efficiency.

- Precision Measurement: To ensure utmost precision, our automation systems are equipped with advanced measurement capabilities. Utilizing rulers and precise measurement tools, we meticulously verify dimensions and alignment throughout the molding process, guaranteeing accuracy and consistency in the final products.

- Cost Efficiency: By automating key aspects of the molding process and minimizing manual intervention, Ritech’s solutions lead to significant cost savings. Increased productivity, reduced labor costs, and minimized material waste contribute to enhanced operational efficiency and profitability.

- Flexibility and Scalability: Ritech’s automation solutions are designed to be highly adaptable and scalable, accommodating varying production requirements and evolving business needs. Whether scaling up production volumes or diversifying product lines, our solutions can be tailored to meet your specific demands.

Applications:

- Semiconductor manufacturing

- Electronics and telecommunications

- Optics and photonics

- Solar energy

- Medical device manufacturing

- Aerospace and defense

Partner with Ritech for Advanced Quartz Molding Automation

Ready to revolutionize your quartz molding processes with advanced automation? Contact Ritech today to explore how our tailored solutions can optimize efficiency, reduce costs, and drive success in your operations. With Ritech as your partner, you can achieve unparalleled precision and efficiency in quartz molding, elevating your production capabilities to new heights.